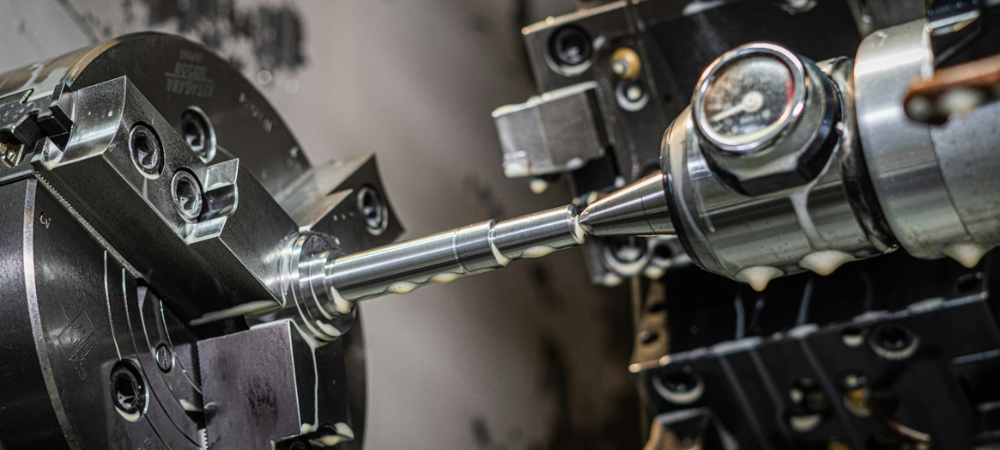

CNC Machining

_

Our CNC machining services provide precise, high-quality machining solutions for complex parts. Utilizing state-of-the-art 3-axis and 5-axis CNC machines, we offer accurate and efficient production of parts, tailored to meet your exact specifications. We deliver parts with tight tolerances and consistent quality, ensuring each component meets your specific requirements. Our CNC machining services accommodate a wide range of materials and complex designs, making us capable of producing parts in various shapes and sizes.

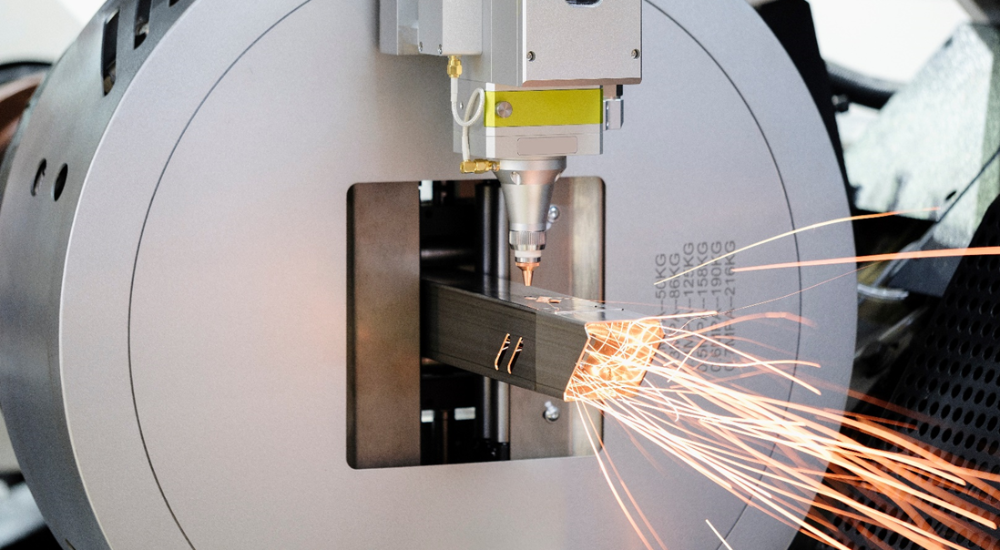

Laser Cutting

_

Our laser cutting services offer precision, speed, and versatility for a wide range of industrial applications. Using state-of-the-art laser technology, we deliver highly accurate cuts on various materials, enabling us to meet the most demanding specifications with exceptional quality. We can cut a wide range of materials with different thicknesses. Whether you need to process steel, aluminum, or any other metal, our laser cutting services are equipped to handle both small and large production runs with quick turnaround times. We ensure consistent quality, regardless of the production volume.

Laser Tube Cutting

_

Our laser tube cutting services are designed to deliver precision and efficiency for complex tubular structures and components. We can cut a wide range of materials, including steel, stainless steel, aluminum, and other metals. Our services are not limited to standard circular tubes; we can also cut square, rectangular, and other custom-shaped tubes with ease. Our laser cutting process produces clean, smooth, and burr-free edges, eliminating the need for secondary finishing operations. This results in a higher quality product with reduced lead times, minimal material waste and lower costs.

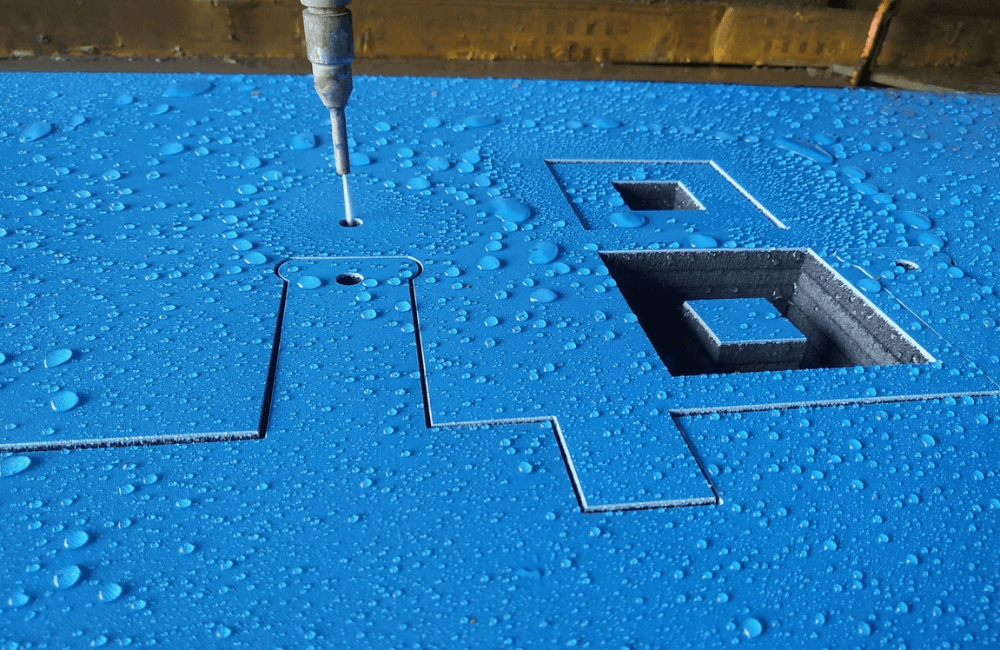

Waterjet Cutting

_

Our waterjet cutting services provide unparalleled precision and versatility, making them ideal for cutting a wide variety of materials. We cut broad range of materials, including metals, plastics, composites, and even delicate materials like rubber and foam. This versatility makes it a go-to solution for diverse industrial applications. As a cold cutting process, waterjet cutting does not generate heat, eliminating the risk of heat-affected zones, warping, or material distortion. This makes it ideal for cutting heat-sensitive materials and maintaining the material’s original properties. Our capabilities include state-of-the-art 3-axis and 5-axis waterjet machines equipped with three cutting heads. This advanced setup allows us to provide faster turnaround times, enabling us to meet tight deadlines while maintaining top-tier quality.

Press Brake Bending

_

We work with a wide range of materials, including steel, stainless steel, aluminum, and other metals. Whether you need thick, heavy-gauge metal or delicate, thin-sheet metal bent to specific angles, our press brakes are capable of handling various materials and thicknesses. We serve various industries, including automotive, aerospace, construction, electronics, and more. We produce components that meet the specific demands of each sector, ensuring they are ready for immediate use in your projects.

CNC Tube Bending

_

We offer precise, efficient, and customizable solutions for forming tubes and pipes to exact specifications. Utilizing advanced CNC technology, we deliver high-quality bends that meet the demands of various industries, from automotive to aerospace and beyond. We can bend a wide range of tube materials, including steel, stainless steel, aluminum, copper, and more. Our services accommodate various tube diameters and wall thicknesses, allowing us to meet the specific needs of diverse applications. We are capable of handling both small and large production volumes with quick turnaround times, ensuring that your project stays on schedule.

Welding

_

Our expertise covers a broad spectrum of welding methods, allowing us to accommodate a wide range of materials and applications:

- MIG (Metal Inert Gas) Welding: Ideal for thicker materials, MIG welding provides strong, clean welds with high productivity, making it suitable for various industrial applications.

- TIG (Tungsten Inert Gas) Welding: Known for its precision, TIG welding is perfect for thin materials and applications where high-quality, aesthetically pleasing welds are required.

- Spot Welding: Commonly used for joining sheet metal, spot welding is efficient and effective, particularly in high-volume production environments.

Value Added Assembly Services

_

Our value-added assembly includes integrated services such as:

- Sub-Assembly: Pre-assembling components into sub-assemblies to streamline final assembly and reduce overall production time.

- Quality Control and Testing: Implementing rigorous quality control measures and testing procedures to ensure that each product meets your specifications and industry standards.

- Packaging and Labeling: Providing custom packaging solutions and detailed labeling to facilitate efficient handling, distribution, and traceability.